Step 2

Processing

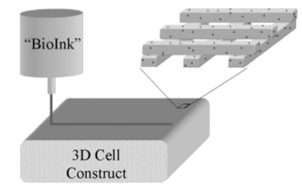

After the blueprint is designed, the next step involves the actual printing and solidification of the organ through devices designed to deliver and deposit material onto some form of substrate. Using the CAD drawing or blueprint, the layer-by-layer placement of natural materials (cells or aggregates) can be achieved using a bioprinter. The bioink must be created and prepared, resulting in bioink droplets containing a single cell or cell aggregates, and loaded into a biocartridge. The bioink is sent through a syringe-like nozzle and deposited onto the biopaper in a controlled manner. The precise placement of the cells is directed by blueprint or model, producing desired cell patterns and/or constructs. In addition, each layer of cells may be separated by a thin layer of biomimetic hydrogel that enable the resulting 3D tissue structure after the gel layer relaxes and tissue fusion occurs.

A favorable approach to generating 3D scaffolds and tissue structures is the use of inkjet printers due to their ability for fast delivery speeds of at least 600 drops per second and inexpensive cost, already in use in the development of devices such as drug screening tools and biosensors. Inkjet printing uses a computer to acquired digitized data (that represents an image) to reproduce it by depositing cells in an ink drop onto a substrate. Studies have already demonstrated cell survival through printing and consistent delivery of one cell per ink drop. Rapid prototyping technologies are an alternative method for designing scaffolds but there are many challenges in controlling the precise placement and positioning of cells into the 3D scaffold and factoring in any risks due to high temperatures and use of toxic resin.

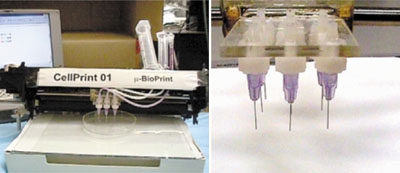

Step 2 of the bioprinting process is ideally similar to stereolithography (use of cells in photosensitive hydrogel for precise placement using a mask or dielectrophoresis or directing the cells) in the proposed simultaneous layer-by-layer deposition of cells and stimuli sensitive hydrogel. The general idea is to have a cost-effective automatic robotic bioprinting device that would enable precise and controlled deposition. Current scientists and researchers have developed bioprinters/deposition devices using robotically-controlled syringe-like delivery tools similar to the cell printer displayed above. The magnified image on the right focuses on the print head consisting of nine nozzles for depositing material.

This image provides a schematic representation of the simultaneous layer-by-layer printing and deposition of cells (and scaffold). The magnified cross-section displays the layered structure.