Although the primary concern is to mimic the function of the

native heart valve, there are secondary considerations that need to be

addressed as well. The secondary

considerations revolve around minimizing unwanted side effects that result from

the design of the prosthetic valve.

- Biocompatibility

– Materials used must not provoke an immune response. This means presenting infection as well

as thrombosis or calcification that may impede the operation of the new

valve.

- Durability

– Heart valves are expected to work continuously for several years and are

implanted though a major invasive surgery.

For these two reasons, we cannot afford to have valves fail

prematurely (see figure 4).

- Manufacturability

– The construction of the valve should be feasible and consistent. This requires us to consider materials

that have high yield rates. The

design must be able to be constructed reasonably (see next consideration).

- Cost –

The cost of the valve must be reasonable and competitive with similar

products. Even if all of the above

design considerations were perfectly met, there would be resistance in the

marketplace if the cost of the valve were too high.

|

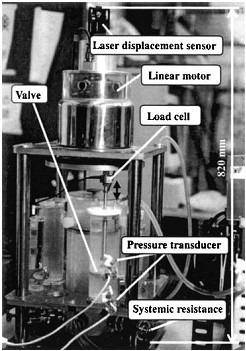

Figure 4: An accelerated heart

vavle wear tester. To ensure that heart valve designs can

withstand the constant forces and motion, machines such as this are

used to simulate the number of cardiac cycles the valves are expected to

endure through their expected lifetime. Thus, several years worth

of valve activity are compressed into a few weeks or months. |