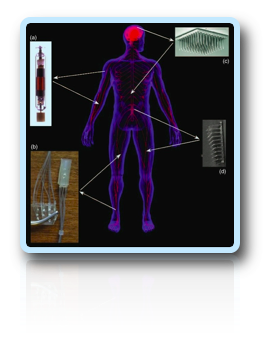

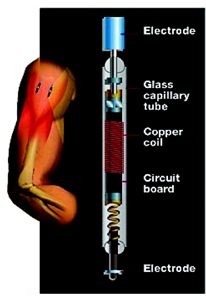

The design considerations for the fabrication of microminiature devices include: size (diameter and length), device encapsulation, power (source), physical range, number of channels, pulse width control (sec), pulse amplitude control (mA), pulse waveform, and waveform options [5].

The main distinguishing feature of microstimulator-based applications is that multiple stimulators can be implanted with minimal surgery. The size and shape of the device is restricted to a cylindrical capsule to permit injection through a hypodermic needle. A second feature of the device concerns the control of multiple implants. Each device must contain circuitry that is uniquely addressable and capable of delivering a variety of pulse durations and intensities. A third feature is long life, which requires that internal components of the stimulator be electronically isolated from the body fluids, and power and data be transmitted through RF coupling [1].

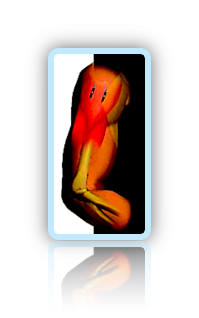

The microminiature implantable electronic devices are designed such that they can be used in a variety of combinations to stimulate individual nerves and muscles. These devices eliminate the donning and reliability problems of surface and percutaneous electrodes, and do not require long leads between the electrodes and the controller because the receiving and stimulating circuitry are contained within each unit. Their small size allows injection directly into the desired muscles through a hypodermic needle, providing for unlimited combination of a multiple of individually selective channels [1].

Go to BME 240 Homepage

Back

Next