Mechanical Valves

| The first replacement heart valves were constructed of synthetic materials, and are known as "mechanical" valves. This first design dates to the 1950's and is known as the “ball in cage” design. An occluder ball functions as the valve while housed in a restraining cage. The assembly is attached using a sewing ring at the base of the cage. The ball is usually made of silicon rubber, while the material used for the cage evolved from acrylic to stainless steel and finally to a cobalt-chromium alloy. Use of these materials made ball in cage valves remarkably durable. However, the relatively simple design did not exactly mimic the function of the native valve. This is because the position of the ball when the valve was in the open position disrupted the blood flow (see figure 5). | ||

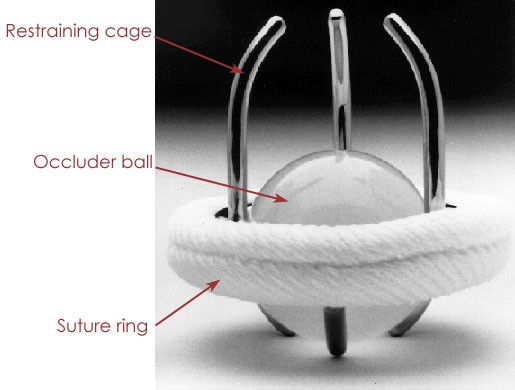

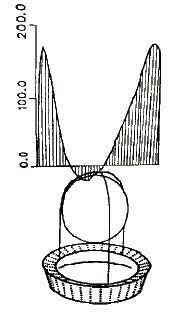

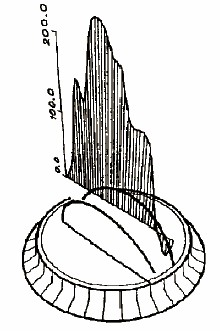

Figure

5: Left: The ball-in-cage prosthetic heart valve design. The

occluder ball replaced the leaflets of the native valve as the method

for regulating directional flow. Right: The primary drawback to

this design is a flow profile (graph denotes flow velocity) that is

disrupted towards the center due to the presence of the ball.

|

||

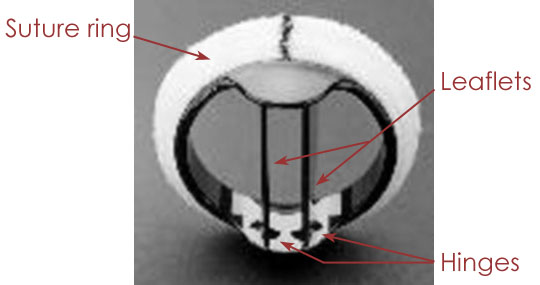

| Thus, a new design was needed. During the 1960’s, designs using leaflets

were developed (see figure 6). These leaflets were

comprised of small panels that tilted to open and close the valve. Initial designs incorporated a single leaflet

made of pyrolytic carbon-coated graphite with a centralized pivot point. The low profile of the leaflet increased the

laminar flow when compared with a ball in cage valve. The current design, dating to 1979 (see figure 7), uses two

leaflets. Each is shorter than the

single leaflet design, which allows them to open completely, parallel to the

bulk flow of blood. This creates less

turbulence, and this design closely replicates the parabolic flow profile around a native heart

valve. |

||

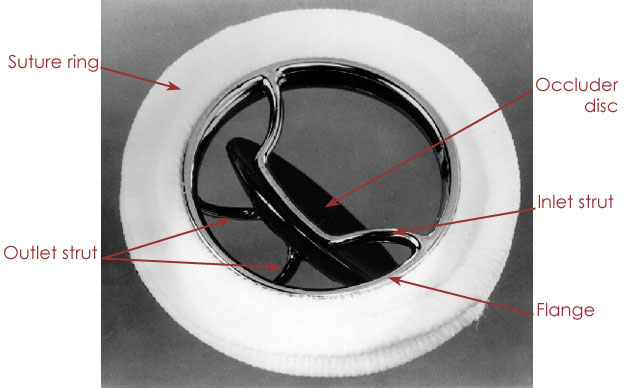

Figure

6: Left: Single leaflet mechanical valve design. Right: Velocity

(cm/s) as a function of position through the valve. Although

there is still obstruction at the center of the flow profile, this

volume is reduced compared to the ball in cage model.

|

||

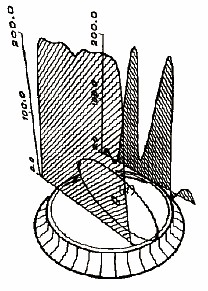

Figure

7: Left: Bileaflet design is more symmetric in nature. Right:

Velocity profile is biased towards the center, as also observed in

native heart valves.

|

||

| The primary drawback for mechanical heart valves is the

biocompatibility of the materials used.

Blood clotting and thrombus formation which would compromise the opening

and closing of the leaflets are common with mechanical valves, and as a result,

patients using these devices are usually put on anti-coagulant drugs. These drugs essentially turn all patients

into hemophiliacs. They can also cause

birth defects and as a result, mechanical heart valves are not suitable for

women who want to have children. Despite these drawbacks, mechanical heart valves remain a viable option due to their extreme durability. |

Page design and content by Vincent Nguyen-Hoai