1. Design Challenge - Microscale

|

|

The graphs

above

demonstrate some of the design limitations of microsensor technology.

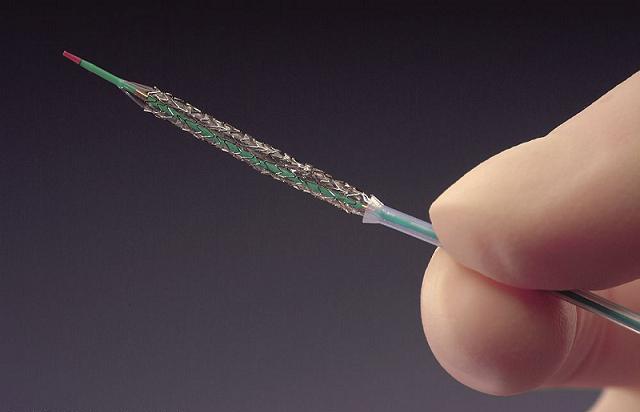

Figure on

the left shows a common intravascular stent implantation procedure for

higher

severity stenotic lesions. The metal stent surrounds the deflated

balloon

catheter (green) which, in turn, sits on top of the guide wire (red).

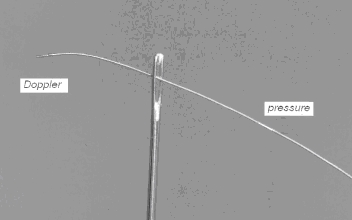

In order

to confirm re-establishment of blood flow past the lesion site,

pressure, flow

and temperature sensors would need to fit inside a 0.36 mm diameter

wire shown

on the right. This constitutes a significant design challenge and one

that has

just recently been overcome by new sensor fabrication protocols

discussed below.

|

|

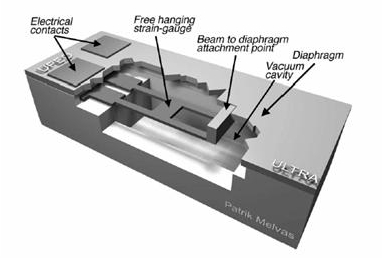

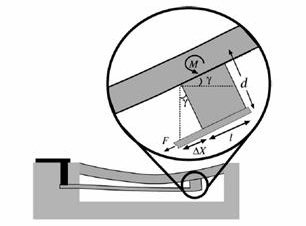

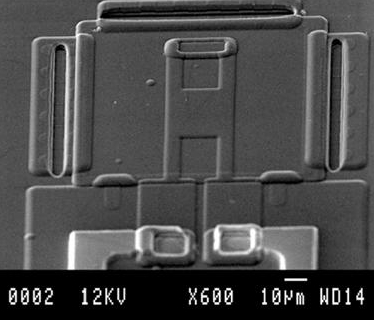

The figures

above

show a blow up view of an early microsensor based on a deflectable

polysilicon

diaphragm and a free-hanging polysilicon piezoresistor that changes

resistance

in response to torque-induced strain (right). The electrical bonding

pads

behind the piezoresistor attachment point send current in order to

monitor the

strain induced changes in resistance and feedback the signal along the

length

of the wire to an external source. The width and height of the chip

overall are

less than 0.2 mm which allows the chip to be secured to the 0.36 mm

diameter

guide wire.

This shows

an SEM

micrograph of the chip that is integrated into the flexible guide wire

mesh

design.